Modern thermal energy storage (TES) systems are integrated with artificial intelligence (AI) applications to make their performance more energy efficient and reliable. AI-based energy systems have developed fault detection models with accuracies ranging from 85% to 95% and lower rates of false alarms to speed up power restoration times.

These systems are characterized by the way they capture live data about temperature, pressure conditions, and flow rates, and monitor them in real time. Thus, they are capable of early detection of any anomaly. The interpretation of data from many sensors allows AI to foresee faults and warn technicians so they can take immediate corrective action. Energy loss and damage to equipment are far less or avoided altogether, while the life length of TES systems is optimized. Providing AI capability in TES indeed makes them intelligent energy storage systems that operate optimally and safely.

Many older systems rely on simple rules and manual checks. This can lead to problems being spotted too late. Examples include:

Even inspections that fall within normal ranges may be so spaced apart that they give small faults ample time to grow unnoticed into bigger ones. Practically, this means that troubles are often found and dealt with only after there has been a consequence. For example, the building staff may find a leaking pipe only after water pools on the floor. It is these gaps in traditional monitoring that allow the problem to outrun the condition it is designed to detect. Dust settles until an alarm sounds, or a technician checks the system, and energy loss or damage has oftentimes already occurred.

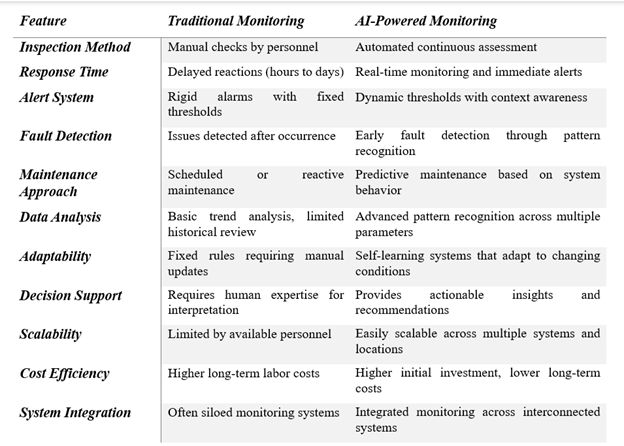

Table 1: Traditional vs. AI-Powered Monitoring

AI continuously analyzes current data from the storage system and has changed the game. The TES sensors are continuously collecting information such as temperature, pressure, and flow rates. Data streams are reviewed and monitored in real-time by AI software. Instead of waiting for an alarm, AI looks for normal patterns in the data and alerts whenever it spots something odd, somewhat like a guard dog or a detective that never sleeps. For instance:

Machine learning models learn these normal patterns from historical data, so they know what "healthy" operation looks like. Even cutting-edge AI methods can identify hidden issues within the real-world messy data.

Real-time AI monitoring helps in the early detection of many common problems with TES:

If they are detected on time, these faults can be fixed earlier, without spending much on downtime or energy.

Figure 1: Common Faults Detected by AI in TES Systems

AI learns the normal operation and recognizes the errors using some intelligent techniques like:

• Anomaly detection: Some AI techniques have been programmed to observe what constitutes "normal" data; then it flags as anomalous anything that deviates far from that norm. (These outliers can often be discovered using methods such as isolation forests or autoencoders.) Over time, it learns normal cycles and can observe even the slightest variations.

• Time-series prediction: However, some models look at historical data and predict something from that, such as what is going to happen next. This is what recurrent neural networks, such as LSTMs (Long Short-Term Memory), do. If the prediction shows something different, then the AI would trigger an alert. An example is at a storage tank; it usually cools at night; suddenly, it doesn’t, so the AI knows something is.

• Sensor fusion: By correlating readings from various sensors, such as temperature, pressure, and flow, AI achieves a more complete representation of a process. If one sensor becomes 'weird,' but all the other inputs are fine, the whole context of fusion aids in helping prevent false alarm triggers. For example, one sensor could read high, while another reads low, so the AI knows that something is 'off.' Artificial intelligence monitoring is used to give forecast programs the present-day analysis of associated variables for providing accurate reports about future developments of forecast conditions.

These intelligent algorithms are mostly unsupervised and intelligent in that they adapt themselves to learn from messy real-life data rather than having fingerprints for explicit faults. They essentially create a normal behavior model and watch over any observed deviations or deviation prediction errors.

Implementing AI for real-time monitoring brings many advantages:

These advantages will definitely add to the benefits of smooth operations with an improvement in energy consumption. Intelligent observation indeed pays off by reducing expenses and preventing emergencies.

Currently, AI-powered monitoring is being found in real systems. Such as:

More intelligent applications for such resilient TES systems may be discovered as AI continues its improvement.

AI integration in the monitoring of thermal energy storage marks a new and complete shift from reactive to proactive management. AI can extend system life by detecting subtle problems before they blossom and facilitate preventive maintenance, thereby reducing instances of unexpected failure. With intelligent monitoring and automated controls, TES systems gain the capacity to adjust their operations and act autonomously, given adequate data inputs. The advantages accrued in this regard go a long way to minimizing downtime and enhancing energy efficiency and operational confidence amongst building managers and engineers alike. AI-powered TES systems are now more reliable in operation and do better work towards fulfilling sustainability objectives, ensuring that energy is not wasted as they perform their operational functions. This further move towards smart monitoring means longer-lasting, dependable thermal storage solutions for a greener future and an assurance of consistent and predictable operation.

Powered by Froala Editor